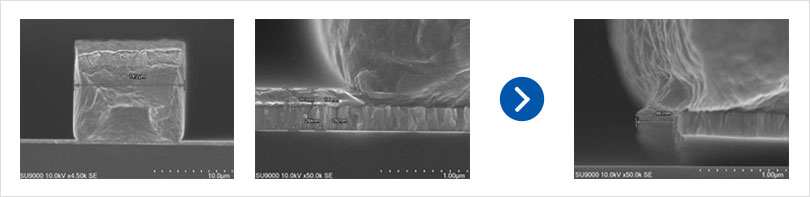

- · E/R : 400~500A/min(at 30 ℃ )

- · Under-cut : Under 1um (150% over etch)

- · Materials : Al, Cu damage free

- Semiconductor Etching Solution

- TiW Etchant

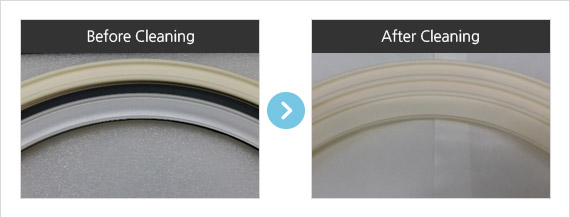

- Cleaning Parts (Non-metal)

- Sealant Cleaning Solution

- · Application : LCD process syringe / bracket / nozzle

- · Improved cleaning power in comparison to Acetone

- · Materials : SUS, PE, PP, PTFE damage free

- Cleaning Parts (Metal)

- AI/Plasma Burn Cleaning Solution

- · Application : Semi-conductor ceramic parts

- · Materials : SUS,Ceramic, PVC, PE, PP, PTFE damage free

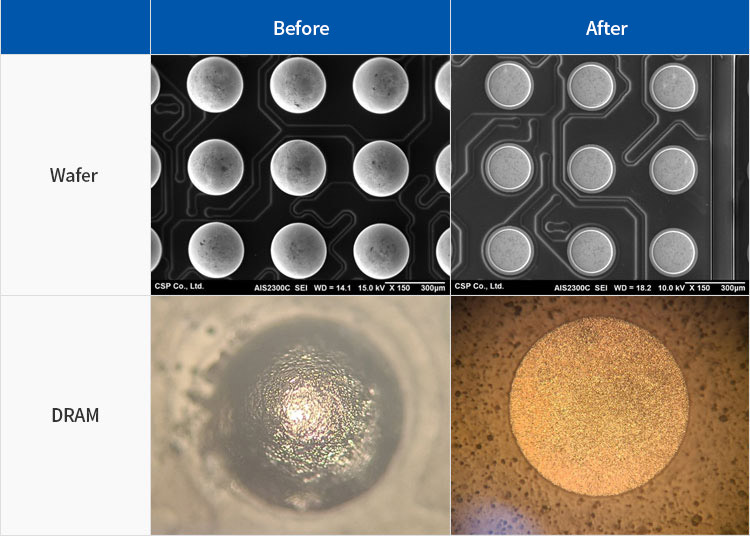

- Solder remover

- For Solder remover wafer

- · E/R : 12~15um/min(at 40℃)

- For Solder remover DRAM

- · E/R : 5~7um/min(at 25℃)

- · IMC damage free(Not Cu protection)

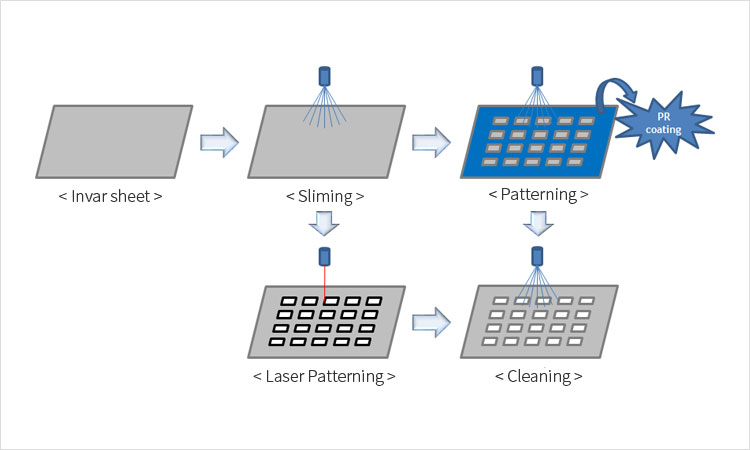

- Invar Mask Total solution

| Division | Purpose | Name | Note |

| Mask production | Sliming&Patterning | CS-313IA | |

| Laser Pattern Cleaning | CS-302MC, CS-303MC | ||

| PR Cleaning | CS-550 | ||

| organic vapor deposition&Initial cleaning | organic vapor deposition&Fluorescent Residue | NMP&CS-700T | |

| Processed oil and Jinhae cleaning | CS-701AC | ||

| inorganic deposition network | inorganic cleaning (AgMg) | CS-100SE | |

| weapon cleaning (LiF) | CS-701AC |

MASK production by process

- · Sliming & Patterning

CS-313A - · Laser Pattern Cleaning

CS-302MC, 303MC - · PR Cleaning

CS-550

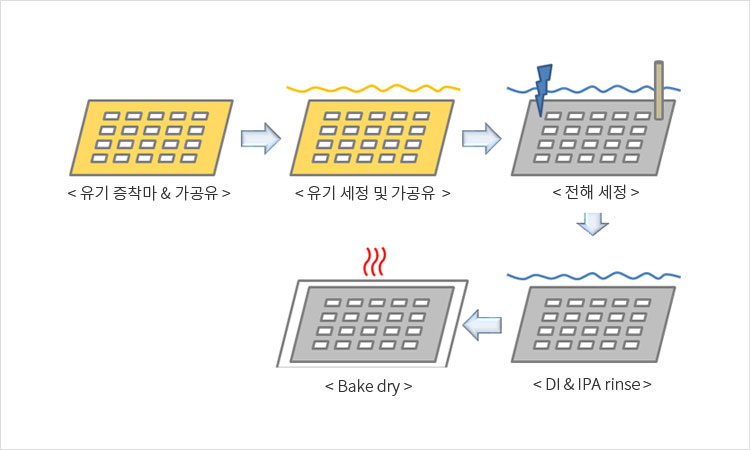

2. Organic deposition film & initial cleaning by process

- · Organic Vapor Deposition & Fluorescent Residue

NMP & CS-700T - · Processing oil and electrolytic cleaning

CS-701AC

3. Inorganic deposition film cleaning

- · inorganic cleaning

(AgMg)

CS-100SE - · inorganic cleaning

(LiF)

CS-701AC