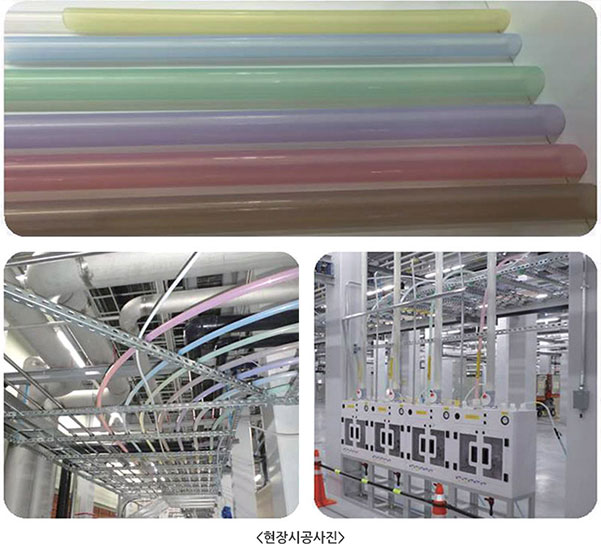

- · 약액별 배관 색상 시공으로 위험요인 최소화 & 눈 관리 효과

- · 장거리 시공으로 Leak Point 최소화

- · 일체형 시공으로 작업 편리성 & 시공비 30% Down

- · 우수한 마모 및 마모저항

- · 사용온도 최대 5000℉ (260℃)

- DUAL CONTAINMENT TUBE

- Features

- EP COIL TUBE

- Maker Introduce

Maker

Introduce

- 특수배관 부품 및 서비스를 제공

- ISO 기준 Class-10 클린룸에서 세정, 테스트, 포장을 진행

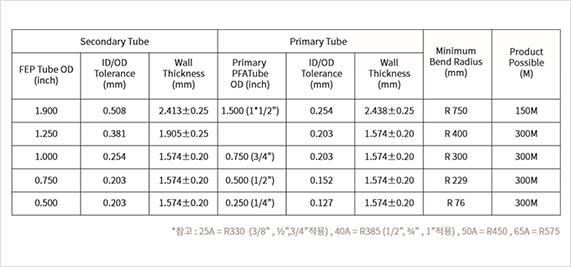

- EP-Coil Tube Evaluation Data

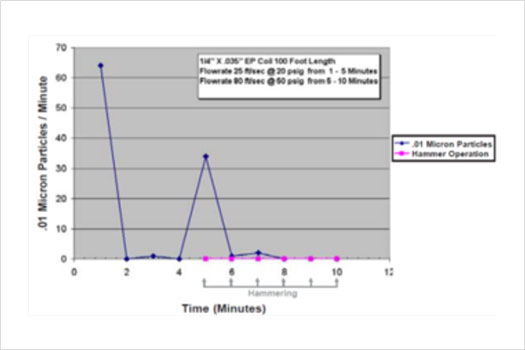

Particle test #1 – 180º Bending → Straight restoration

※ 10Min(분) 이후 Particle 미검출 확인 (사람에 대한 오류도 10분내에 해결)

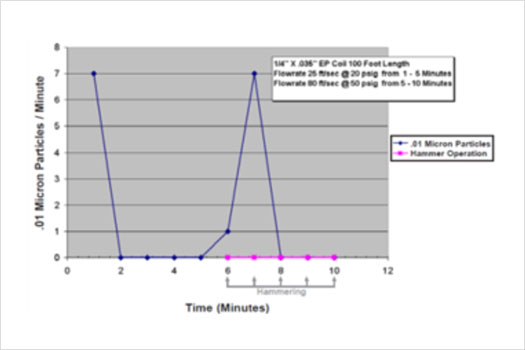

Particle test #2 – Roller Use Straight Bending

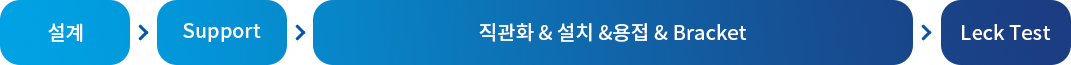

- How to install EP-TUBE (COil : Stick) #1

ⓐ Coil Tube 시공 (개선안)

ⓑ Stick Tube (기존)

- How to install EP-TUBE (COil : Stick) #2

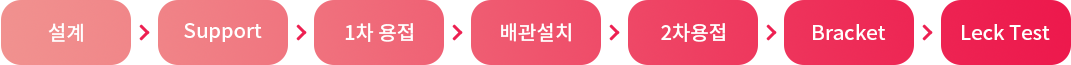

- Why use EP-Coil Tube?

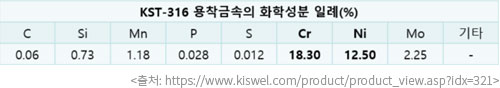

SUS 배관용접

- – 고온의 열로 용접봉을 용융시켜 배관-배관 연결의 방법

- – 용접봉 성분표

Global 기업 EP-Coil 적용

- – TSMC, Intel, Micron 등 2016년부터 신규 라인 적용

EP-Coil Tube 적용

- – 용접 개소 감소 = Weak point 감소 → Metal 용출 point 감소

- – 400M 작업 시 용접 개소

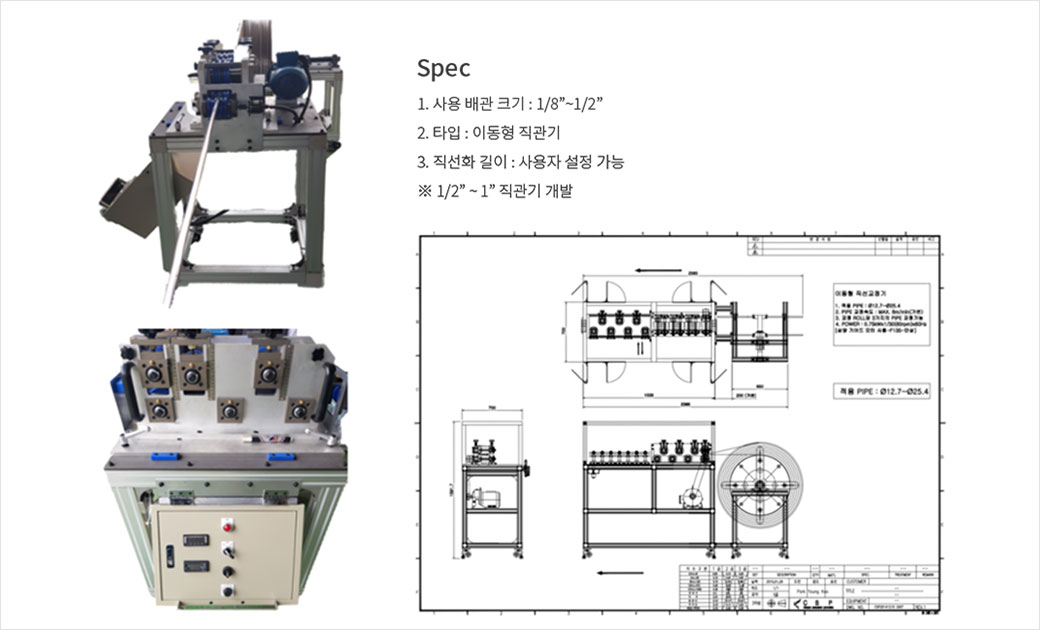

- 직관기

- FFKM 불소 O-RING

- Solrez’s selection guide for process

| Process | Compound Number | Service temp(oC) | Color | Equivalent Compound |

| Metal CVD Process LP-CVD Oxidation Diffusion Lamp Anneal RTP Ash ALD |

8318 | 320 | Light yellow | 4079,8900 7075UP,653 |

| 8107 | 320 | Black | 4079,8900 7075UP,653 |

|

| 9578 | 300 | Light yellow | 9100, 9300M XRZ |

|

| 9575 | 300 | White | 8475, 8575 | |

| 9568 | 280 | Light yellow | 8002 | |

| 9566 | 280 | White | E-38 | |

| Wet Etching Photo litho-graypy Stripping Copper plating |

9308 | 250 | Light yellow | 8002.93 |

| 9307 | 250 | Black | 6375UP | |

| 7709 | 230 | Amver translucent | Amor crystal | |

| 7708 | 230 | Light yellow | Ultic Armor | |

| 6907 | 220 | Black | - | |

| 6607 | 250 | Black | Fluoraz888 | |

| 5901 | 200 | Blue | - |

- Solrez’s Compound selection guide

| Compound number | Service temp(oC) | Color | Equlvalent Compound | Recommend Processing |

| 8318 | 320 | Light yellow | 4079,8900,7075UP,653 | Oxidation diffusion(02,N2,CI2) Metal CVD(NF3,SiH4,F2,CI2) |

| 8107 | 320 | Black | 4079,8900,7075UP,653 | Oxidation diffusion(02,N2,CI2) Metal CVD(NF3,SiH4,F2,CI2) |

| 9578 | 300 | Light yellow | 9100,9300,XRZ | PECVD/ALD/HDPCVD (TMS,SiH4,NH3,NF3,SiF4) |

| 9575 | 300 | White | 8475,8575 | Infrared light |

| 9568 | 280 | Light yellow | 8002 | Ash(2,CF4,NH3,CHF3),Dry etch |

| 9566 | 280 | White | E-38 | Ash(2,CF4,NH3,CHF3),Dry etch |

| 9308 | 280 | Light yellow | 8002,9300 | Wet etch,strip,copper plating (HN03,HF,H3PO4,H202,CuSO4) |

| 9307 | 250 | Black | 6375UP | |

| 7709 | 230 | Amber translucent | Amor crystal | All CVD,Dry etch and plasma ashing equipment For semiconductor and LCD |

| 7708 | 230 | Light yellow | Ultic Armor | |

| 6907 | 220 | Black | - | Excellent solvent resistance(FKM) |

| 6607 | 250 | Black | Fluoraz888 | Wet etch |

| 5901 | 220 | Blue | - | O2,O3 Plasma |

- High temperature FFKM special O-ring

- Grade: Solrez8318

- Material: FFKM

- Service temp: 320℃

- Color: light yellow

- Hardness: 75(shore A)

- Tensile strength: 14.2MPa

- Elongation: 210%

- Compression set: 18%(270℃ x 72hrs)

- Application:

– Oxidation diffusion(O2,N2,CI2)

– Metal CVD(NF3,SiH4,F2,CI2)

- Grade: Solrez8107

- Material: FFKM

- Service temp: 320℃

- Color: Black/li>

- Hardness: 75(shore A)

- Tensile strength: 12.2MPa

- Elongation: 180%

- Compression set: 18%(200℃ x 72hrs)

- Application:

– Oxidation diffusion(O2,N2,CI2)

– Metal CVD(NF3,SiH4,F2,CI2)